|

|

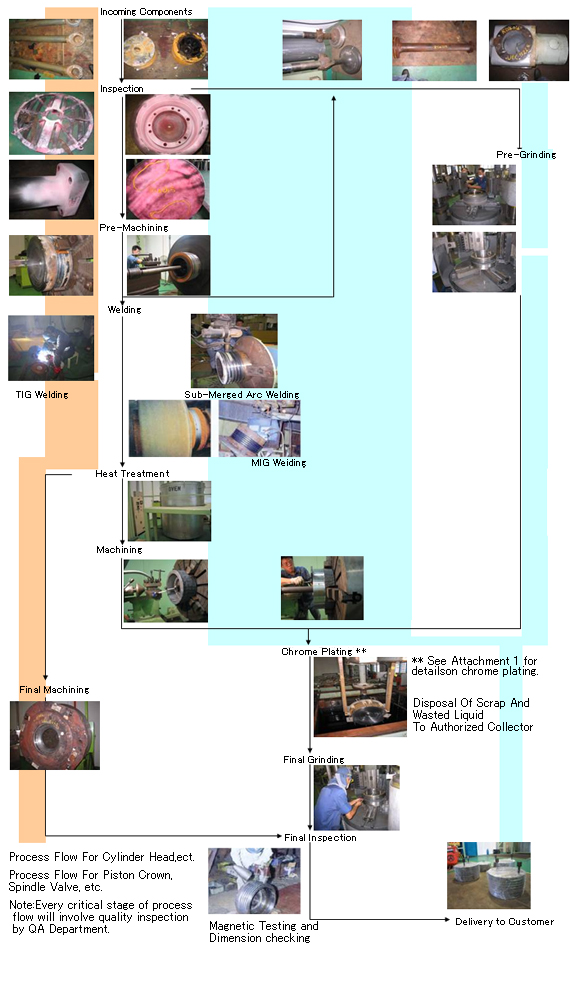

1 Reconditioning

Welding, machining and standardization for any kind of diesel engine components such as piston crown, cylinder cover, exhaust valve spindle seat and any shore power plant machineries.

2 Chrome Plating

Chrome Plating of Diesel Engine components such as Piston Crown, Valve spindle for any kind of Engine.

3 Special Cast Iron Welding

Special Cast iron welding include Crank Bed, Damaged Engine Block, Turbocharger casing,

pump casing and etc.

4 Consultancy and Supervisory Services

Consultancy and supervisory services by our group specialists/experts for any kind of Diesel engine Maintenances/Repair/Trouble shooting works.

5 Others Services

Others mechanical engineering works, repair of marine engine and ship fs parts supply.

6 Surface griding / Honing |

|

|

| |

|

|

| |

|

Inspection/Dimensional report that will advise if the Piston Crowns are within reconditioning limits

Restoration of combustion surface, shoulders and sides to original profiles and dimensions.

Restoration of material loss on piston crown top land by depositing special hard face weld overlays

using specialist welding processes under controlled conditions.

Specialist Post Weld Heat Treatment after welding to ensure reliability of the welded piston crown.

Restoration of piston grooves

Hard chroming of piston grooves

Dressing up landing surfaces, bolt and stud holes

Exchange service for selected Engine Types

Modification of Piston Crowns as per specific Customer specifications |

| |

|

Inspection/Dimensional report that will advise if the valve & seats are within reconditioning limits

Restoration of combustion surface, shoulders, seating/contact area, valve stems,

rotating fins etc to original profiles and dimensions.

Restoration of material loss on Valve underside, shoulder area by depositing special hard face weld

overlays using specialist welding processes under controlled conditions.

Customized Post Weld Heat Treatment after welding to ensure reliability of the reconditioned valve spindle/seat.

Restoration of cooling bores/O ring grooves

Hard chroming/Oxy Fuel Metal spray of valve stems

Dressing up seating surfaces, cooling bores etc.

Exchange service for selected Engine Types |

| |

|

Cleaning, inspection, and recording

Pre-machining, gouging damages or cracks

Building up damages or cracks

Stress relieving

Machine back to size

Crack detection

Final inspection, including hydro-test, and recording

Class survey as per customer request

Rust protection |

| |

|

Cleaning, inspection, and recording

Pre-machining, gouging damages or cracks

Building up damages or cracks

Stress relieving

Machine back to size

Crack detection

Final inspection, including hydro-test, and recording

Class survey as per customer request

Rust protection |

| |

|

|

|

|